Additional module VDA

Characteristics

Fast

Data exchange at your finger tips

Assignment to sales and purchase orders

Packing plans and loading structures

Secure

Test routines at VDA import and export

Integrated

Delivery schedules acc. VDA 4905

Delivery note and transport data acc. VDA 4913

Goods tag acc. VDA 4902

Delivery note acc. VDA 4912

Characteristics

Automaticly

Order creation or order update

Assignment of customer data, delivery addresses, article data

Order creation or order update

Assignment of customer data, delivery addresses, article data

Reliable

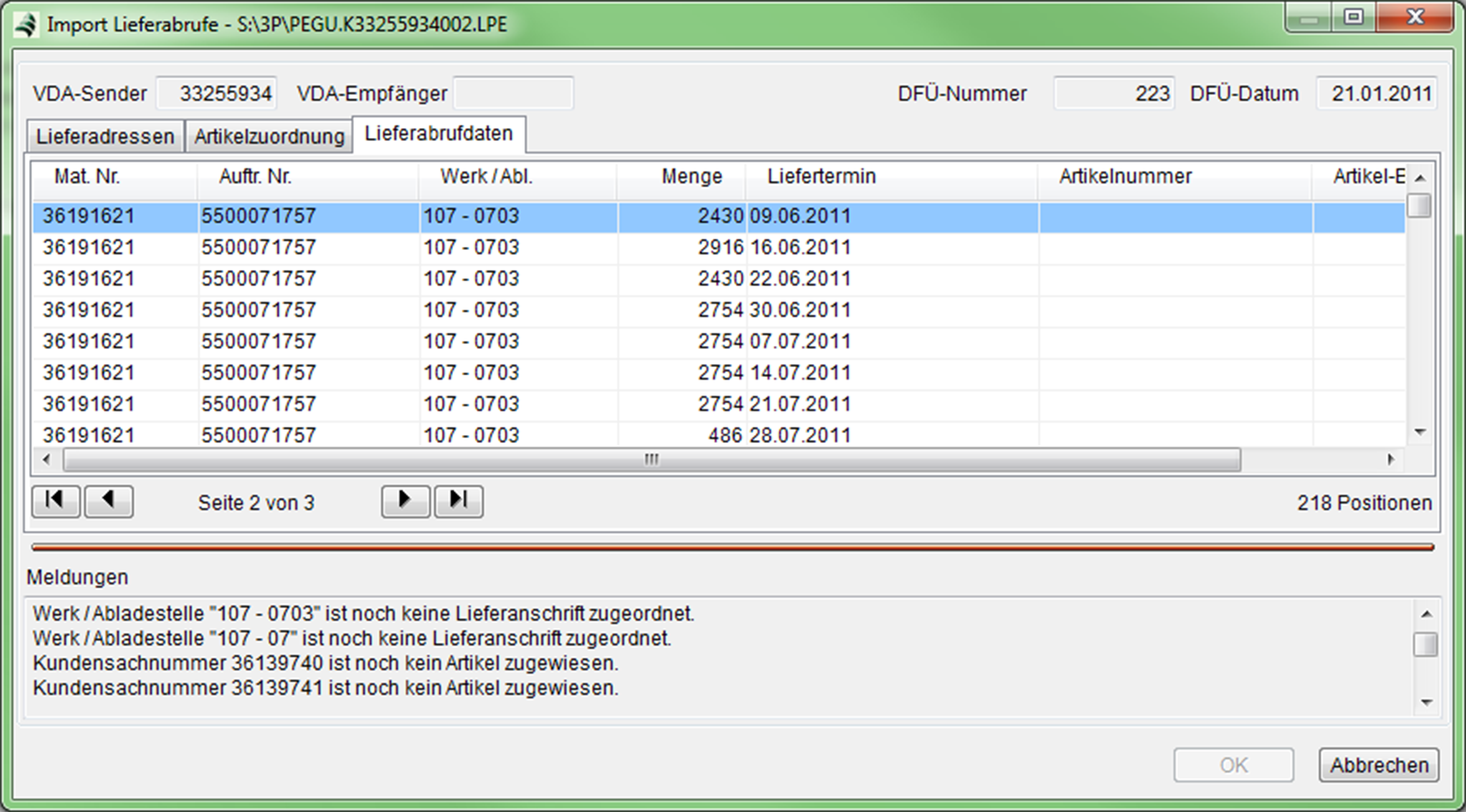

Notes on missing assignments

History of the import for follow-up

Comfortable

Management of plants and unloading points

Characteristics

Efficient

Summary of various orders for a delivery note

Integration of packing plans

Summary of various orders for a delivery note

Integration of packing plans

Clear

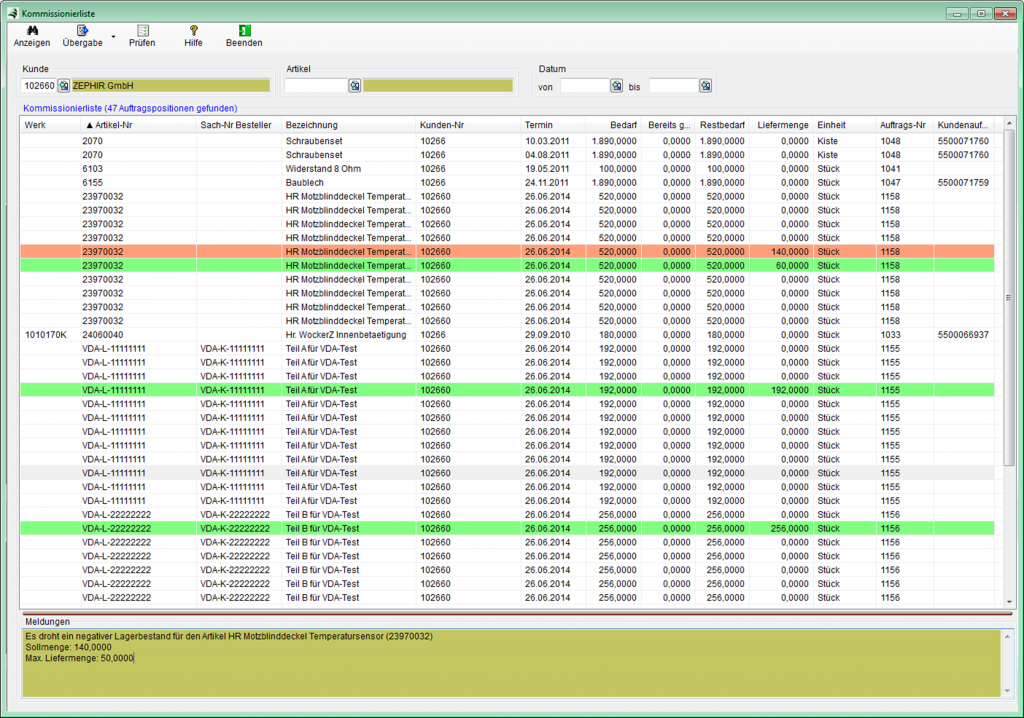

Color coding for the availability of articles

Various filter options (customer, article, delivery date)

Delivery progress

Automatically

Creation of different delivery notes at different delivery addresses / plants / unloading points

Inventory transaction