Production list and production orders

Characteristics

automatic production proposals

Summarize or splitting of orders

productive

Relation to customer order or requirement

anytime changes to Production order possible

manual or automatic inventory control and removal

clear

Production progress

Serial and batch number tracking of materials and the total part possible

customizable production documents

The production list determines the demand for production items. Various filtering options, e.g. according to orders, according to standard, minimum or zero stocks or according to delivery times increase the clarity. The production proposals can be transferred directly to production orders. Here, both the summarization and the splitting of orders is possible.

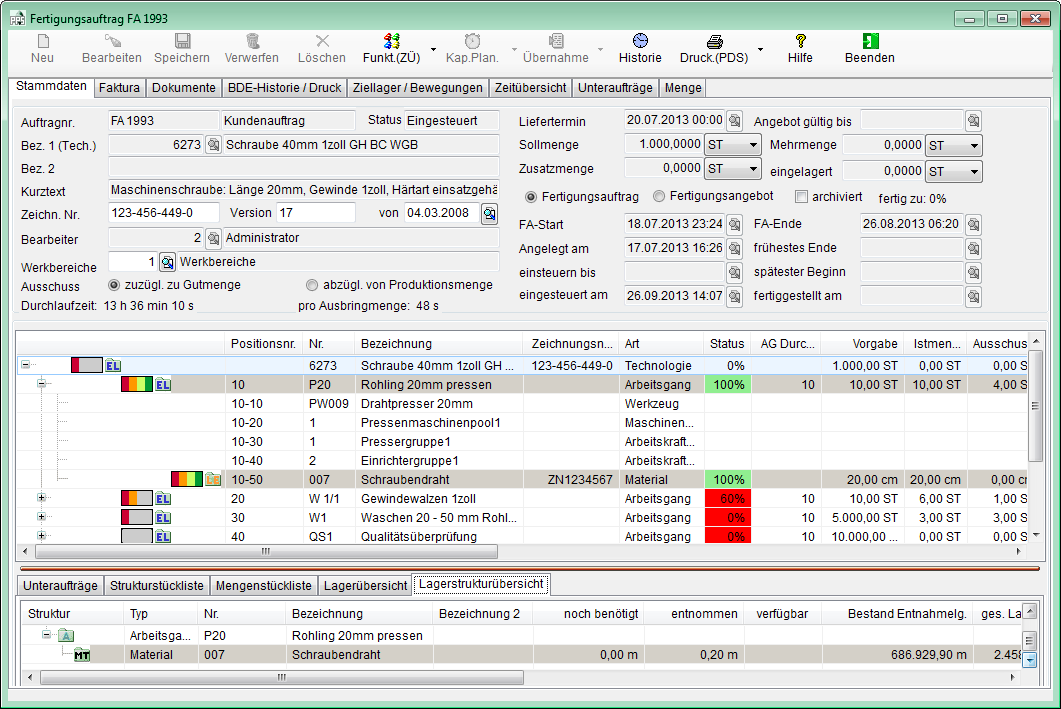

In the menu Production Orders, you can view the status of your orders and create new production orders. Here

a manual or automatic (work-driven) material disposition is possible. With the taxes and the

When all manufacturing documents are printed, the production order is released for production. In the production order, all information such as reports of personnel and machine times, material procurement and withdrawals, taking into account series or batch numbers, completion of individual operations, scrap notifications and storages, are merged. Third-party services can also be ordered directly from the production order. The production progress is displayed graphically. Changes during the manufacturing process are possible at any time. With the finishing and the final costing you finish the production export.

Production order